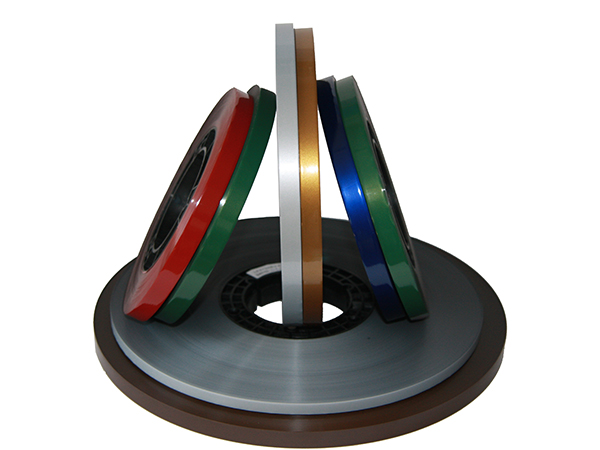

| Item | L film | K film |

| Package | Black poly bag | Blue poly bag |

| Winding direction | Coating on inner side | Coating on outside |

| Film color | Cream white(light pink) | White |

| Thickness | 1/2/3LW:95±10µm 4/5LW:90±15µm MW:85±10µm | 1/2/3LW:90±15µm 4/5LW:85±15µm MW:90±15µm |

| Precision | ±10% or less (measured by densitometer at 23℃,65% RH) | |

| Recommend temperature | 1/2/3LW,MW:20℃-35℃ 4/5LW:15-30℃ | |

| Recommend humidity | 1/2/3LW,MW:35%RH-80% RH 4/5LW:20%-75%RH | |

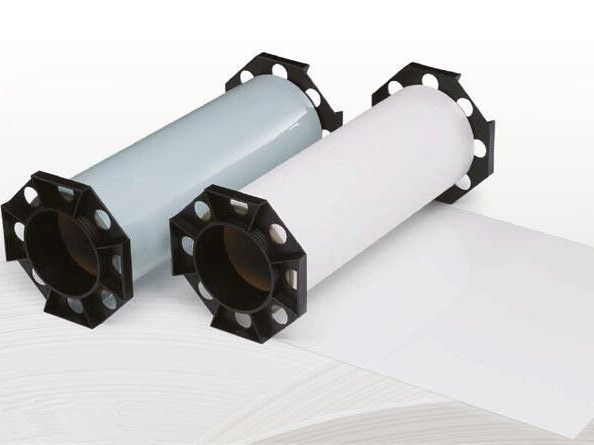

| Item | MS film | PET Protection Film |

| Package | Black poly bag | Inside the roller |

| Winding direction | Coating on inner side | No coating |

| Film color | Cream white(light pink) | Transparent |

| Thickness | 105±10µm | 75µm |

| Precision | ±10% or less (measured by densitometer at 23℃,65% RH) | |

| Recommend temperature | 20℃-35℃ | |

| Recommend humidity | 35%RH-80% RH | |

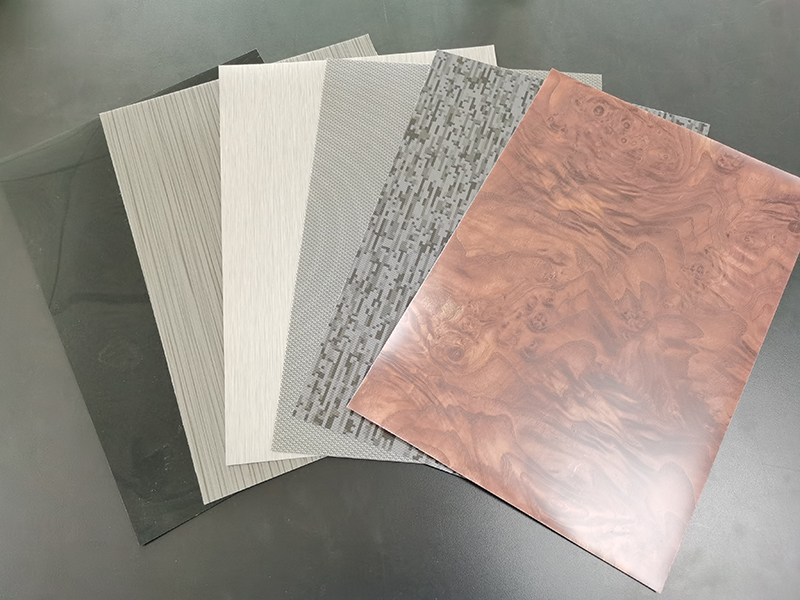

TWO-SHEET:

MONO-SHEET:

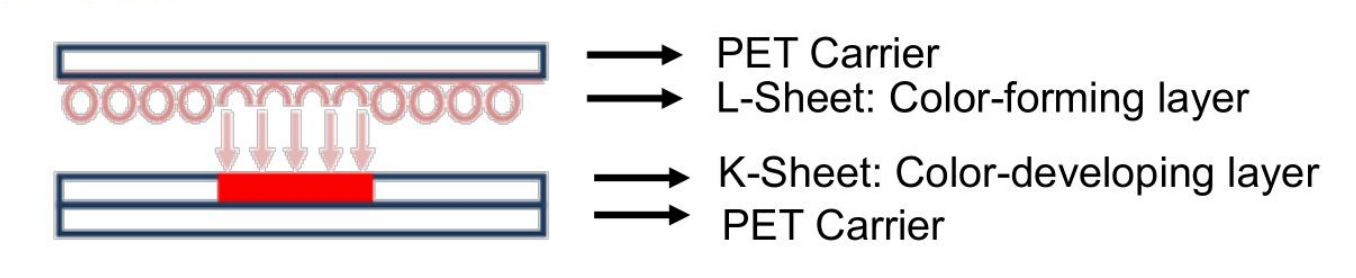

MONO-SHEET:  Working Principle Face the coated sides of L-Sheet and K-Sheet, apply pressure, the microcapsules of L-Sheet are broken,color forming material of L-Sheet reacts with color developing material of K-Sheet, red color appears. The damage degree of microcapsules is according to pressure level. The greater the pressure, the greater the damage of microcapsules and the higher the color density. On the other hand, the lower the color density.(1) Avoid direct sunlight ,away fire in original packaging. (2) Storage the film below 15℃. (3) Keep unused film in the black and blue poly sacks and store then in a box.

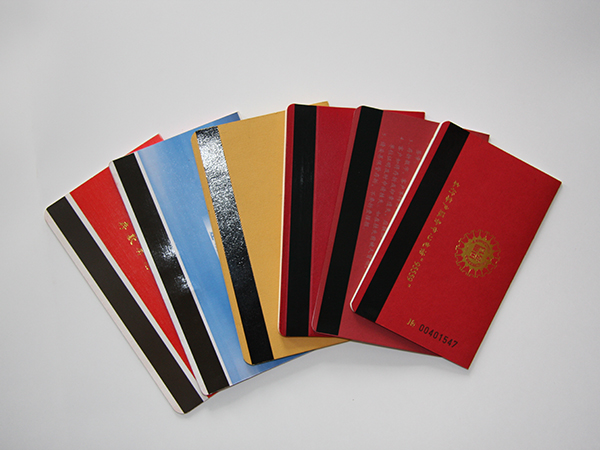

Working Principle Face the coated sides of L-Sheet and K-Sheet, apply pressure, the microcapsules of L-Sheet are broken,color forming material of L-Sheet reacts with color developing material of K-Sheet, red color appears. The damage degree of microcapsules is according to pressure level. The greater the pressure, the greater the damage of microcapsules and the higher the color density. On the other hand, the lower the color density.(1) Avoid direct sunlight ,away fire in original packaging. (2) Storage the film below 15℃. (3) Keep unused film in the black and blue poly sacks and store then in a box.| Product code | Width | Length | Pressure Range(Mpa) | Type |

| Ultra Extreme Low Pressure 5LW | 310mm | 2m | 0.006-0.05 | Two sheet |

| Extreme Low Pressure 4LW | 310mm | 3m | 0.05-0.2 | Two sheet |

| Ultra-Super Low Pressure 3LW | 270mm | 5m | 0.2-0.6 | Two sheet |

| Super Low Pressure 2LW | 270mm | 6m | 0.5-2.5 | Two sheet |

| Low Pressure 1LW | 270mm | 10m | 2.5-10 | Two sheet |

| Medium Pressure (MW) | 270mm | 10m | 10-50 | Two sheet |

| Medium Pressure (MS) | 270mm | 10m | 10-50 | Mono-sheet |