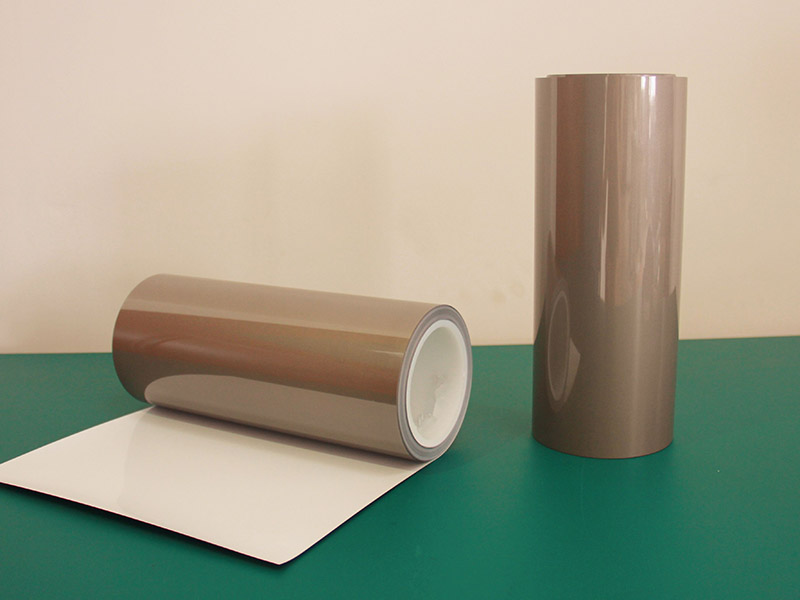

Durable and Stylish Interior Ins Film for Automotive Use

By:Admin

{Company Name} is at the forefront of producing high-quality Automotive Interior Ins Film, with a long-standing reputation for excellence and innovation in the industry. With a focus on research and development, the company has consistently delivered cutting-edge products that meet the needs of car owners and manufacturers alike.

The {Company name} Automotive Interior Ins Film is designed to provide a protective barrier for car interiors, safeguarding against wear and tear, spills, and stains. This durable film is made from premium materials that are both scratch-resistant and easy to clean, ensuring that vehicle interiors remain in pristine condition for years to come. Additionally, the film is available in a range of finishes and textures, allowing car owners to customize their interiors to their liking.

One of the key advantages of {Company name} Automotive Interior Ins Film is its ease of installation. Unlike traditional interior protection methods, such as seat covers or floor mats, the film can be seamlessly applied to all interior surfaces, including upholstery, dashboards, and door panels, without the need for adhesives or fasteners. This not only provides a sleek and professional look but also ensures that the film will not interfere with the functionality of the vehicle's interior components.

Furthermore, the film is designed to be long-lasting, providing durable protection that stands the test of time. This means that car owners can enjoy peace of mind knowing that their investment is well-protected, and their vehicle's interior will maintain its value over the long term.

{Company name} is committed to providing top-notch customer service, offering comprehensive support to car owners and automotive professionals alike. With a dedicated team of experts, the company is able to provide guidance on product selection, installation techniques, and maintenance tips, ensuring that customers get the most out of their Automotive Interior Ins Film.

In addition to its commitment to high-quality products and customer support, {Company name} emphasizes sustainability and environmentally friendly practices. The company's manufacturing processes are designed to minimize environmental impact, and its products are made from eco-friendly materials that adhere to strict industry standards.

As the automotive industry continues to evolve, {Company name} remains at the forefront of innovation, developing new products and solutions to meet the changing needs of car owners and manufacturers. The Automotive Interior Ins Film is just one example of the company's dedication to providing cutting-edge solutions that make a tangible difference in the automotive market.

Overall, {Company name} Automotive Interior Ins Film is a game-changer for car owners looking to protect and enhance their vehicle interiors. With its superior quality, ease of installation, durability, and environmental considerations, the film is a must-have for anyone looking to maintain the value and aesthetics of their vehicle. As the automotive industry continues to embrace this innovative solution, {Company name} is poised to lead the way with its commitment to excellence and innovation.

Company News & Blog

Durable Foil Shielding Tape for Effective Cable Protection

Foil Shielding Tape: The Latest Innovation in EMI Shielding TechnologyIn today's fast-paced and technology-driven world, electromagnetic interference (EMI) has become a major concern for a wide range of industries. EMI can disrupt the functioning of electronic devices, leading to malfunctions, loss of data, and even system failure. As a result, companies are constantly seeking innovative solutions to protect their electronic equipment from EMI.One such solution that has been gaining attention in the industry is Foil Shielding Tape, a cutting-edge product that offers superior EMI shielding capabilities. This innovative tape is designed to provide a robust barrier against electromagnetic interference, ensuring the smooth and uninterrupted operation of electronic devices in various applications.One of the leading companies at the forefront of developing and manufacturing Foil Shielding Tape is {}. With a rich history of over 30 years in the industry, {} has established itself as a renowned supplier of high-quality EMI shielding materials. The company's commitment to excellence and innovation has enabled it to stay ahead of the curve and deliver state-of-the-art solutions to its customers.The Foil Shielding Tape offered by {} is engineered to meet the demanding requirements of modern electronics and telecommunications systems. It is constructed from high-quality materials, including a thin layer of metallic foil that provides exceptional shielding performance. The tape is also equipped with a strong adhesive backing, ensuring easy application and a secure seal on various surfaces.One of the key advantages of Foil Shielding Tape is its versatility. It can be used in a wide range of applications, including cable shielding, grounding, and EMI protection for electronic enclosures. Whether it's in aerospace, automotive, telecommunications, or consumer electronics, {}'s Foil Shielding Tape is a reliable choice for addressing EMI challenges across different industries.In addition to its superior shielding capabilities, Foil Shielding Tape offers other benefits such as excellent conductivity, flexibility, and resistance to environmental factors. These qualities make it an ideal solution for protecting electronic devices from external interference and maintaining their optimal performance under diverse operating conditions.With the increasing demand for advanced EMI shielding solutions, {} has continued to advance the development of Foil Shielding Tape to meet the evolving needs of its customers. The company invests heavily in research and development, leveraging the latest technologies and industry insights to enhance the performance and durability of its products.Furthermore, {} places a strong emphasis on quality and reliability, ensuring that its Foil Shielding Tape complies with international standards and regulations. This commitment to excellence has earned the company a solid reputation for delivering premium EMI shielding solutions that meet the highest industry standards.As the industry continues to evolve, the demand for effective EMI shielding solutions will only grow. With its cutting-edge Foil Shielding Tape and unwavering dedication to innovation, {} is well-positioned to address the complex challenges of EMI protection, providing its customers with the confidence and peace of mind that their electronic equipment is well-protected.In conclusion, Foil Shielding Tape is a game-changing innovation in EMI shielding technology, offering superior protection for electronic devices across various industries. Through its expertise and commitment to excellence, {} has emerged as a leading supplier of high-quality EMI shielding materials, providing its customers with reliable solutions to safeguard their critical electronic equipment. As the industry continues to advance, {} remains at the forefront, driving innovation and setting new benchmarks for EMI shielding performance.

Transform Your Space with Interior Film: A Cost-Effective Solution for Redecorating

Ins Interior Film, an industry leading interior film company, is making waves in the world of interior design with their innovative and high-quality products. With a focus on providing customers with a wide range of options for transforming their spaces, Ins Interior Film has quickly become a go-to choice for designers, architects, and homeowners alike.The company offers a diverse selection of interior film products, including wood grain, marble, fabric, and metallic finishes. These films can be easily applied to a variety of surfaces, such as walls, furniture, and countertops, allowing for endless design possibilities. Whether it's creating a sleek, modern look or adding a touch of luxury to a space, Ins Interior Film has the perfect solution for every project.One of the key factors that sets Ins Interior Film apart from its competitors is the quality of its products. The company uses cutting-edge technology and the highest quality materials to ensure that their films are not only beautiful, but also durable and long-lasting. This commitment to excellence has earned Ins Interior Film a reputation for delivering outstanding results that stand the test of time.In addition to their exceptional product quality, Ins Interior Film also prides itself on providing exceptional customer service. The company's team of experts is dedicated to helping customers find the perfect interior film solution for their specific needs. From offering expert advice on design options to providing professional installation services, Ins Interior Film is committed to ensuring that every customer has a seamless and satisfying experience.Ins Interior Film's dedication to innovation and excellence has earned the company a loyal following of satisfied customers. Designers and homeowners alike have praised the company for its ability to transform spaces quickly and affordably, without compromising on style or quality. With Ins Interior Film, achieving a stunning, custom look has never been easier.In addition to their line of interior film products, Ins Interior Film also offers a range of accessories and tools to facilitate the installation process. This includes adhesive solutions, cutting tools, and other essential supplies for achieving a flawless finish. The company's goal is to provide everything customers need to successfully complete their interior film projects with ease and confidence.With a commitment to quality, innovation, and customer satisfaction, Ins Interior Film has solidified its position as a leader in the interior design industry. Whether it's for a residential, commercial, or hospitality project, the company's products and services continue to be a top choice for those looking to elevate their spaces with style and functionality.As Ins Interior Film continues to expand its product line and reach new markets, the company remains dedicated to upholding its standards of excellence. With a focus on delivering superior products and exceptional service, Ins Interior Film is poised to remain a go-to source for interior design solutions for years to come. Whether it's creating a custom look for a single room or executing a large-scale project, customers can trust Ins Interior Film to deliver exceptional results every time.

Innovative Flatness Measurement Instruments for Precision Manufacturing

Flatness Measurement Instruments has recently been making waves in the manufacturing industry with its high-precision flatness measurement technology. With a focus on providing accurate and reliable measurement solutions, the company has quickly established itself as a leading provider of flatness measurement instruments.The company's flatness measurement instruments are designed to meet the demanding requirements of modern manufacturing processes. By utilizing advanced technology and precision engineering, the instruments offer unparalleled accuracy and reliability in measuring flatness. This allows manufacturers to ensure the quality and precision of their products, ultimately leading to improved efficiency and cost savings.One of the key features of Flatness Measurement Instruments' products is their ability to measure flatness with incredible precision. The instruments use state-of-the-art sensors and measurement algorithms to achieve accuracy levels that were previously unattainable. This level of precision is essential for industries such as aerospace, automotive, and semiconductor manufacturing, where even the slightest deviation from flatness can have a significant impact on product performance.In addition to their precision, Flatness Measurement Instruments' products are also known for their ease of use and versatility. The instruments are designed to be user-friendly, allowing operators to quickly and easily perform flatness measurements without the need for extensive training. Furthermore, the instruments are capable of measuring flatness across a wide range of surfaces and materials, making them suitable for a variety of applications.Another noteworthy aspect of Flatness Measurement Instruments is their commitment to continuous innovation and improvement. The company is dedicated to staying at the forefront of flatness measurement technology, constantly developing new techniques and solutions to meet the evolving needs of the industry. This commitment to innovation ensures that customers can always rely on Flatness Measurement Instruments for the latest and most advanced measurement solutions.Flatness Measurement Instruments has also built a strong reputation for its exceptional customer service and support. The company's team of experts is readily available to provide technical assistance, training, and guidance to customers, ensuring that they are able to maximize the value of their flatness measurement instruments. This dedication to customer satisfaction has earned Flatness Measurement Instruments a loyal and satisfied customer base.Furthermore, Flatness Measurement Instruments is also committed to sustainability and environmental responsibility. The company is constantly seeking ways to minimize its environmental impact, from using energy-efficient manufacturing processes to reducing waste and emissions. This eco-friendly approach is not only beneficial for the environment but also reflects the company's values and commitment to corporate social responsibility.As Flatness Measurement Instruments continues to grow and expand its presence in the manufacturing industry, the company remains dedicated to providing cutting-edge flatness measurement solutions that empower manufacturers to achieve the highest levels of quality and precision. With its focus on innovation, precision, and customer satisfaction, Flatness Measurement Instruments is poised to continue making a significant impact on the industry for years to come.

High-Quality Emi Shielding Mesh Tape for Effective Electromagnetic Interference Protection

EMI Shielding Mesh Tape: Your Solution for Electromagnetic InterferenceIn today's fast-paced and highly technological world, electromagnetic interference (EMI) has become a prevalent issue. EMI can disrupt the functioning of electronic devices and equipment, leading to malfunctions, data corruption, and even complete system failure. As a result, there is a growing need for effective EMI shielding solutions to protect electronic devices and ensure their proper functioning. This is where EMI Shielding Mesh Tape, developed by {Company Name}, comes into play.{Company Name} has been a leading provider of innovative solutions for EMI shielding and electromagnetic compatibility (EMC) for over two decades. Their extensive experience and expertise in this field have enabled them to design and manufacture high-quality EMI shielding materials that meet the stringent requirements of various industries, including telecommunications, aerospace, medical devices, automotive, and consumer electronics.EMI Shielding Mesh Tape is one of {Company Name}'s flagship products, and it has garnered widespread acclaim for its superior performance and reliability. This innovative tape is designed to provide effective EMI shielding for a wide range of applications, including cable harnessing, printed circuit boards, connectors, and electronic enclosures. The tape is made from a flexible and conductive mesh material, which allows it to conform to complex shapes and provide complete coverage for the components it protects.One of the key advantages of EMI Shielding Mesh Tape is its easy application. The tape features a pressure-sensitive adhesive backing, which makes it simple to apply to various surfaces without the need for special equipment or expertise. This ease of use allows for quick and cost-effective installation, saving time and resources for manufacturers and engineers.Furthermore, EMI Shielding Mesh Tape is highly durable and reliable, ensuring long-term performance and protection against EMI. The tape is resistant to abrasion, chemicals, and environmental factors, making it suitable for use in harsh industrial environments and extreme conditions. Its robust construction and superior shielding capabilities make it an ideal choice for applications where dependable EMI protection is critical.In addition to its excellent shielding properties, EMI Shielding Mesh Tape also offers important benefits for design and manufacturing processes. The tape is lightweight and thin, which minimizes its impact on the overall size and weight of the protected components. This is particularly important for applications where space and weight are at a premium, such as aerospace and automotive electronics.As a socially responsible company, {Company Name} is committed to sustainable and environmentally friendly practices. EMI Shielding Mesh Tape is manufactured using eco-friendly processes and materials, ensuring minimal impact on the environment. This dedication to sustainability reflects {Company Name}'s broader commitment to corporate social responsibility and ethical business practices.To further support its customers, {Company Name} offers comprehensive technical support and customization options for EMI Shielding Mesh Tape. Their team of experienced engineers and specialists is available to provide expert advice and guidance on choosing the right shielding solution for specific applications. {Company Name} also offers custom design and manufacturing services to meet the unique requirements of their clients, ensuring that the tape delivers optimal performance and value.In conclusion, EMI Shielding Mesh Tape from {Company Name} is a cutting-edge solution for EMI protection in electronic devices and equipment. Its superior shielding capabilities, ease of application, durability, and environmental sustainability make it an ideal choice for a wide range of industries. By choosing EMI Shielding Mesh Tape, engineers and manufacturers can ensure the reliability and performance of their electronic devices, even in the face of challenging EMI conditions. With {Company Name}'s extensive expertise and commitment to customer satisfaction, customers can trust that they are getting the best EMI shielding solution available on the market.

Guide to Using Positive Dry Film Photoresist for Your Projects

Positive Dry Film Photoresist (PDP) is a cutting-edge technology that has been gaining significant attention in the electronics and semiconductor industries. With its innovative features and high performance, PDP is redefining the way in which photoresist materials are used in the manufacturing process.{Company name} is at the forefront of this groundbreaking technology, offering a wide range of PDP products that cater to the diverse needs of its customers. The company has been a pioneer in the development and production of advanced materials for electronic applications, and its expertise in photoresist technology has positioned it as a trusted partner for leading manufacturers around the world.One of the key advantages of PDP is its ability to deliver superior quality and precision in the photolithography process. This is crucial in the production of intricate electronic components, where accuracy and consistency are paramount. PDP enables manufacturers to achieve finer patterns and higher resolution, resulting in enhanced product performance and reliability.In addition, PDP offers excellent adhesion and uniformity, which ensures that the photoresist adheres effectively to the substrate. This stability is essential for the successful transfer of the pattern during the etching and deposition processes, ultimately contributing to the overall quality of the finished product.Furthermore, PDP is highly resistant to environmental factors, such as temperature and humidity, making it an ideal choice for demanding manufacturing environments. This robustness and durability minimize the risk of defects and ensure the consistency of the production process, leading to improved yield and cost-effectiveness for manufacturers.{Company name} has leveraged its extensive research and development capabilities to create a comprehensive portfolio of PDP products that cater to the specific requirements of different applications. Whether it is for the production of advanced semiconductor devices, printed circuit boards, or flat-panel displays, the company offers tailored solutions that meet the highest industry standards.Moreover, {Company name} is committed to sustainability and environmental responsibility, and its PDP products are designed to comply with stringent regulations and guidelines. This emphasis on eco-friendly manufacturing aligns with the growing demand for green technologies and underscores the company’s dedication to delivering solutions that are both efficient and environmentally conscious.As the demand for high-performance electronic components continues to grow, there is a growing need for advanced materials that can meet the evolving requirements of the industry. With its unparalleled expertise and innovative product offerings, {Company name} is well-positioned to address these needs and drive the adoption of PDP technology in the global market.In conclusion, Positive Dry Film Photoresist represents a significant advancement in the field of photoresist materials, offering unparalleled quality, performance, and reliability. {Company name} stands at the forefront of this technology, delivering a diverse range of PDP products that are tailored to the specific needs of its customers. With its commitment to innovation and sustainability, the company is poised to play a pivotal role in shaping the future of electronic manufacturing and driving the industry towards greater efficiency and excellence.

New innovative foil technology revolutionizes laser printing

Laser Foil, a leading company in the field of pioneering laser technology, has announced the launch of their latest innovative product. The new product is expected to revolutionize the way that various industries utilize laser technology, and is already generating a significant amount of excitement and enthusiasm within the industry.Laser Foil is known for its cutting-edge and high-quality laser technology solutions, and has built a strong reputation for innovation and excellence in the field. The company's commitment to research and development has allowed them to consistently stay ahead of the curve, and their latest product release is a testament to their ongoing dedication to pushing the boundaries of what is possible with laser technology.The new product, which is a result of extensive research and development efforts, promises to deliver a range of benefits to businesses across a wide variety of industries. With its advanced features and capabilities, the product is expected to offer improved performance, efficiency, and cost-effectiveness, making it an attractive option for companies looking to enhance their operations.One of the key features of the new product is its versatility. It has been designed to be compatible with a wide range of materials and surfaces, allowing it to be used in a variety of applications. This flexibility opens up new possibilities for businesses, enabling them to explore new ways to leverage laser technology in their operations.In addition, the new product is designed with user-friendliness in mind. Laser Foil has worked to ensure that the product is easy to use and integrate into existing workflows, minimizing disruption and streamlining the adoption process for businesses. This focus on usability is expected to make the product highly accessible to a wide range of users, further expanding its potential impact.Furthermore, the new product boasts enhanced performance capabilities, setting it apart from other solutions currently available in the market. Its advanced technology enables it to deliver precise and efficient results, allowing businesses to achieve their goals with a high degree of accuracy and reliability. This level of performance is expected to drive significant value for users, empowering them to accomplish more with greater confidence and certainty."We are incredibly excited to introduce our latest product to the market," said a spokesperson for Laser Foil. "We believe that it has the potential to make a significant impact across a wide range of industries, and we are eager to see the ways in which businesses will leverage its capabilities to achieve their goals. This product represents the next step in the evolution of laser technology, and we are proud to be at the forefront of this exciting development."As businesses continue to seek ways to improve their operations and stay ahead of the competition, the launch of Laser Foil's latest product represents a major advancement in the realm of laser technology. With its impressive features and capabilities, the product has the potential to drive meaningful improvements for businesses across various industries, opening up new opportunities and possibilities.Laser Foil's ongoing commitment to innovation and excellence positions them as a leading provider of laser technology solutions, and their latest product release only serves to further solidify their standing within the industry. As businesses look to the future and explore new ways to leverage technology to achieve their objectives, Laser Foil stands ready to support them with cutting-edge solutions that deliver real value.In conclusion, the launch of Laser Foil's latest product is a significant development that is poised to impact businesses across a wide variety of industries. With its advanced features, user-friendly design, and enhanced performance capabilities, the product represents a major leap forward in the realm of laser technology. As businesses look to improve their operations and capitalize on new opportunities, Laser Foil's latest offering is positioned to play a key role in driving progress and innovation within the industry.

New Dry Film Technology: A Breakthrough in Sensitive Material Manufacturing

Sensitive Dry Film, a revolutionary product developed by a leading company in the field of advanced materials, has been making waves in the industry. The product, which is designed to provide superior protection and performance in a variety of applications, has seen significant demand from a wide range of industries.The company behind Sensitive Dry Film, (company name), is a renowned innovator in the development of cutting-edge materials and technologies. With a strong commitment to research and development, the company has continuously pushed the boundaries of what is possible within the materials industry. Their team of experts and scientists has worked tirelessly to create products that offer exceptional performance, reliability, and value to their customers.Sensitive Dry Film is a prime example of the company's commitment to innovation and excellence. The product is a high-performance coating that can be applied to a variety of surfaces, providing a protective barrier that is resistant to wear, tear, and corrosion. It is also designed to be environmentally friendly, with a low VOC content and a non-toxic formulation.One of the key features of Sensitive Dry Film is its ability to provide superior protection in harsh environments. The product has been extensively tested and proven to withstand extreme temperatures, moisture, and chemical exposure, making it an ideal choice for use in a wide range of applications. Whether it is used in the automotive, aerospace, marine, or industrial sectors, Sensitive Dry Film has demonstrated exceptional durability and performance.In addition to its superior protection properties, Sensitive Dry Film also offers excellent adhesion and flexibility. This allows for easy application and ensures that the coating remains intact even under the most challenging conditions. This makes it a highly versatile product that can be used in a variety of ways, from protecting metal surfaces from corrosion to providing a protective barrier for electronic components.The versatility of Sensitive Dry Film has made it a popular choice among manufacturers and engineers in a variety of industries. The product has been successfully used in the automotive sector, where it has been applied to various components to provide long-lasting protection and enhanced performance. It has also been utilized in the aerospace industry, where its ability to withstand extreme temperatures and harsh conditions has made it an ideal choice for use in aircraft components.Furthermore, Sensitive Dry Film has been widely adopted in the marine industry, where its resistance to moisture and corrosion has made it an essential product for protecting boats, ships, and other marine equipment. Its ability to provide long-term protection in saltwater environments has made it a favorite among marine engineers and technicians. Additionally, the product has found applications in the industrial sector, where it has been used to protect machinery, equipment, and infrastructure from wear, tear, and chemical exposure.With its exceptional performance and versatility, Sensitive Dry Film has quickly become a go-to solution for companies and industries looking to enhance the performance and longevity of their products and equipment. The product has consistently delivered on its promise of superior protection, reliability, and value, earning the trust and confidence of customers in a wide range of sectors.Moving forward, (company name) continues to lead the way in the development of advanced materials and technologies, bringing to market innovative solutions that address the evolving needs of industries around the world. With its strong commitment to research and development, the company is well-positioned to continue delivering cutting-edge products like Sensitive Dry Film that offer exceptional performance and value to its customers.

Discover the Benefits of Photosensitive Dry Film for Your Photographic Projects

Photosensitive Dry Film: Revolutionizing PCB ManufacturingIn today's fast-paced world, the demand for electronics continues to grow exponentially. From smartphones to laptops, from automobiles to medical devices, electronics are an indispensable part of our daily lives. Behind the scenes, Printed Circuit Boards (PCBs) form the backbone of electronic devices, providing the necessary connectivity and functionality. As the demand for smaller, faster, and more complex electronic devices increases, the need for advanced PCB manufacturing processes becomes increasingly pressing. One such process that is revolutionizing PCB manufacturing is the use of Photosensitive Dry Film. Photosensitive Dry Film is a key component in the manufacturing of PCBs, as it is used to transfer circuit patterns onto the PCB substrate. This innovative technology has streamlined the PCB manufacturing process, allowing for quicker, more precise, and cost-effective production. With the ability to create intricate circuit patterns and produce finer traces and spaces, Photosensitive Dry Film has become an essential tool for manufacturers looking to stay ahead in the competitive electronics market.One company that has been at the forefront of Photosensitive Dry Film innovation is {}. With a strong focus on research and development, {} has developed Photosensitive Dry Film products that have set new industry standards. Its dedication to creating high-quality, reliable, and environmentally friendly solutions has earned the company a sterling reputation in the PCB manufacturing industry.{} offers a wide range of Photosensitive Dry Film products that cater to the diverse needs of PCB manufacturers. From high-resolution films for fine line circuitry to dual-cure films for complex multilayer boards, {} provides solutions for every application. Its products are designed to deliver exceptional adhesion, durability, and overall performance, ensuring that manufacturers can achieve the highest quality PCBs with ease.One of the key advantages of {}'s Photosensitive Dry Film products is their excellent dimensional stability and uniform thickness, which is crucial for achieving precise and consistent circuit patterns. This level of precision is essential for the production of modern PCBs, which are becoming increasingly complex and compact. With {}'s Photosensitive Dry Film, manufacturers can confidently produce PCBs with intricate designs and tight tolerances, meeting the ever-evolving demands of the electronics industry.In addition to its cutting-edge products, {} offers comprehensive technical support and expertise to its customers. The company's team of experienced professionals is dedicated to helping manufacturers overcome any challenges they may face in the PCB manufacturing process. Whether it is recommending the most suitable Photosensitive Dry Film product for a specific application or providing troubleshooting assistance, {} is committed to ensuring the success of its customers.Furthermore, {} is committed to sustainability and environmental responsibility. Its Photosensitive Dry Film products are designed with the environment in mind, utilizing eco-friendly materials and manufacturing processes. By prioritizing sustainability, {} is not only contributing to a greener future but also helping its customers meet their own environmental goals.As the demand for smaller, more powerful electronic devices continues to grow, the role of Photosensitive Dry Film in PCB manufacturing will only become more critical. With {}'s innovative products and unwavering commitment to excellence, manufacturers can be confident in their ability to meet the evolving needs of the electronics industry. {}'s Photosensitive Dry Film is truly revolutionizing PCB manufacturing, paving the way for the next generation of electronic devices.

Pressure Test Film: A New Innovation in Paper Technology

Fuji Paper, a leading manufacturer of high-quality paper products, recently announced the development of a new pressure test film that is set to revolutionize the industry. The pressure test film, which is designed to accurately measure the amount of pressure exerted on a surface, is expected to be a game-changer for companies across a wide range of sectors.The pressure test film utilizes cutting-edge technology to provide accurate and reliable measurements of pressure. This innovative product is specifically designed for applications where precise pressure measurements are crucial, such as in manufacturing, construction, and automotive industries. The film is capable of detecting pressure variations as low as 2 psi, making it an invaluable tool for quality control and performance testing.One of the key advantages of the Fuji pressure test film is its ease of use. The film can be easily applied to any surface, and the pressure exerted on the film leaves a visible imprint that can be accurately measured using specialized analysis tools. This simple and straightforward process makes it ideal for a wide range of applications, from monitoring the pressure distribution in manufacturing processes to testing the impact resistance of materials.In addition to its accuracy and ease of use, the Fuji pressure test film is also highly versatile. It can be used to measure both static and dynamic pressure, and is compatible with a variety of surfaces, including metals, plastics, and composites. This versatility makes it an invaluable tool for companies looking to improve the quality and performance of their products.The development of the pressure test film is a testament to Fuji's commitment to innovation and excellence. With over [number] years of experience in the paper industry, Fuji has a proven track record of delivering high-quality, reliable products to its customers. The company's dedicated team of engineers and researchers have worked tirelessly to develop the pressure test film, and their efforts have resulted in a product that is set to make a significant impact in the market.In addition to the pressure test film, Fuji offers a wide range of other paper products, including specialty papers for printing, packaging, and industrial applications. The company's extensive product line is known for its exceptional quality, reliability, and performance, making Fuji a trusted partner for companies around the world.As the demand for high-quality paper products continues to grow, Fuji is poised to meet the needs of its customers with innovative solutions like the pressure test film. The company's dedication to excellence and its commitment to ongoing research and development position it as a leader in the industry, and companies can rely on Fuji to deliver the cutting-edge products they need to succeed.In conclusion, the introduction of the Fuji pressure test film represents a significant milestone for the company and the industry as a whole. With its advanced technology, ease of use, and versatility, the pressure test film is set to revolutionize the way companies measure and monitor pressure in a wide range of applications. As Fuji continues to push the boundaries of what is possible in the paper industry, companies can look forward to even more innovative solutions that will help them achieve their goals and stay ahead of the competition.

White Coating Substrate: What You Need to Know

PVC White Coating Substrate revolutionizes the industry with its unparalleled quality and innovative technology. This new product from {Company Name} has set a new benchmark in the field of coatings with its exceptional features and benefits.{Company Name} is a leading manufacturer and supplier in the coatings industry, with a mission to provide high-quality products to its customers. With years of expertise and experience, the company has become a trusted name in the market, known for its commitment to excellence and customer satisfaction.The brand new PVC White Coating Substrate is the result of extensive research and development at {Company Name}, aiming to address the growing demands for a superior coating solution. The substrate is designed to offer outstanding performance and durability, making it the ideal choice for a wide range of applications.One of the key features of the PVC White Coating Substrate is its exceptional adhesion properties, ensuring a strong and long-lasting bond to the surface. This makes it suitable for use in various industries, including construction, automotive, and marine. Its resistance to moisture and harsh weather conditions further adds to its appeal, making it a reliable choice for both indoor and outdoor applications.In addition to its durability, the PVC White Coating Substrate also offers excellent coverage and finish. Its smooth and even coating provides a professional look, enhancing the aesthetic appeal of the surface it is applied to. This makes it a popular choice among architects, designers, and contractors who prioritize a high-quality finish for their projects.Furthermore, the substrate is easy to apply, saving time and effort for the users. Its user-friendly nature makes it a preferred choice for professionals and DIY enthusiasts alike, providing a hassle-free application process without compromising on the quality of the finish.{Company Name} prides itself on its commitment to sustainability and environmental responsibility. The PVC White Coating Substrate is no exception, as it is designed to meet the highest environmental standards. It is free from harmful chemicals and toxins, making it a safe and eco-friendly choice for environmentally conscious consumers.With its outstanding attributes and versatile applications, the PVC White Coating Substrate has already garnered attention and accolades from customers and industry experts alike. Its introduction is set to revolutionize the coatings market, offering a superior solution that meets the diverse needs of the industry.As {Company Name} continues to expand its product line and reach, the PVC White Coating Substrate stands as a testament to the company's commitment to innovation and excellence. With its unmatched quality and performance, it has set a new standard for coatings, cementing {Company Name}'s position as a leader in the industry.For those looking for a reliable, durable, and high-quality coating solution, the PVC White Coating Substrate from {Company Name} is the answer. Its exceptional features and benefits make it a standout choice, catering to the needs of various industries and applications. As the market continues to evolve, {Company Name} remains at the forefront, providing innovative solutions that redefine the possibilities in coatings.